Five-axis Machining for Patterns: Precision Templates for Casting

Date:2026-01-29Article editor:Starting Point PrecisionViews:32In the demanding world of metal casting, the journey from design to final component hinges on a critical first step: the pattern. This master template defines the cavity within a mold, and its precision directly dictates the quality of the cast part. Today, five-axis machining is revolutionizing the production of these essential tools, enabling the creation of highly complex, accurate, and durable patterns and core boxes with unprecedented efficiency.

Traditional machining methods often required multiple setups to complete a complex pattern, introducing potential errors and increasing lead times. Five-axis technology eliminates these constraints. By simultaneously moving a cutting tool across five different axes, it can approach the workpiece from virtually any angle in a single setup. This capability is indispensable for producing the intricate geometries, deep undercuts, and sculpted surfaces commonly found in aerospace investment casting patterns or automotive sand casting templates.

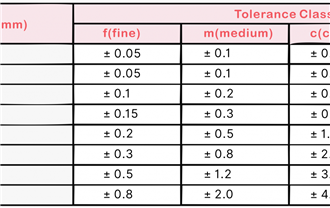

The advantages for foundries and pattern shops are substantial. First and foremost is unmatched precision. Complex contours and critical sealing surfaces can be machined to exceptionally tight tolerances, ensuring the resulting mold cavity is perfect. This precision reduces costly post-casting machining and minimizes material waste. Secondly, it enables design freedom. Engineers can now create optimized patterns with conformal cooling channels or lightweight structures that were previously impossible or prohibitively expensive to make. For more on design for manufacturability, see our guide . Thirdly, single-setup machining drastically reduces production time and human error, accelerating time-to-market.

The applications are vast. In investment casting, five-axis machines expertly craft wax or refractory material patterns with flawless surface finishes. For sand casting, they directly machine the positive patterns from dense plastics, urethanes, or metals like aluminum, creating robust precision master patterns for repeated use. The technology is also perfect for producing matchplates and complex core boxes used in high-volume manufacturing.

Material selection is broad, ranging from high-density modeling foams and industrial-grade plastics to non-ferrous metals. The choice depends on the casting volume, required pattern life, and the molding process (e.g., sand, investment, or die-casting). The ability to machine these diverse materials with the same high accuracy is a key strength of five-axis systems.

Real-world impact is significant. A foundry producing turbine engine components might use five-axis machining to create a monolithic pattern for a single-crystal investment casting, where dimensional integrity is paramount. Similarly, an automotive supplier can rapidly prototype and produce accurate core boxes for engine blocks, streamlining development cycles.

For authoritative information on machining standards, refer to resources from ASM International or SME. To visualize the process, view an example of a five-axis machining a complex pattern :

Looking ahead, the integration of five-axis machining with additive manufacturing (hybrid manufacturing) and advanced scanning for verification is set to further enhance capabilities. This synergy promises even faster turnaround and the ability to correct or modify existing patterns with digital precision.

In conclusion, five-axis machining is more than just an advanced manufacturing process; it is a transformative tool for the casting industry. By delivering superior accuracy, complexity, and speed in pattern making, it lays the literal foundation for higher quality castings, reduced costs, and greater innovation across countless engineering sectors.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 332 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China