CNC Machining Parts Quality Standards: ISO & Industry Certifications

Date:2026-01-31Article editor:Starting Point PrecisionViews:16In the world of precision manufacturing, delivering functional parts is not enough. Consistency, reliability, and traceability are paramount. This is where international quality standards and industry-specific certifications become critical. They provide a verifiable framework that ensures CNC machining suppliers meet the highest benchmarks for quality management and production control.

The Role of Quality Standards in CNC Machining

Quality standards are not just certificates on a wall. They are integrated systems governing every process—from quoting and design review to final inspection and shipping. For buyers, partnering with a certified manufacturer minimizes risk, ensures part interchangeability, and facilitates compliance in regulated industries. Adherence to these standards leads to fewer defects, predictable outcomes, and enhanced supply chain communication.

Foundational ISO Certifications for Quality Management

The International Organization for Standardization (ISO) sets globally recognized benchmarks.

ISO 9001: Quality Management Systems (QMS): This is the cornerstone certification. It demonstrates a company has a robust QMS focused on customer satisfaction, continuous improvement, and consistent processes. While not specific to machining, it is a fundamental indicator of a supplier's commitment to quality.

ISO 14001: Environmental Management: Increasingly important, this certification shows a manufacturer's commitment to minimizing its environmental impact, which is a key consideration for sustainable sourcing.

Critical Industry-Specific Certifications

Beyond foundational standards, specialized industries demand rigorous certifications.

1.Aerospace & Defense: AS9100 / AS9100D

This is the gold standard, built upon ISO 9001 with added requirements for aviation, space, and defense. It emphasizes rigorous risk management, traceability of materials and processes, and stringent control of non-conforming products. Any CNC supplier serving this sector must hold this certification. Learn more about the standard .

2.Medical Devices: ISO 13485

This standard specifies requirements for a quality management system where an organization must demonstrate its ability to provide medical devices that consistently meet regulatory requirements. It places heavy emphasis on documentation, process validation, and sterile manufacturing environments. Compliance is essential for producing surgical tools, implants, and diagnostic equipment.

3.Automotive: IATF 16949

Based on ISO 9001. IATF 16949 is the technical standard for the automotive sector. It includes specific requirements for product safety, manufacturing process capability, and supply chain management. Certification signals a supplier's capability to meet the high-volume, high-reliability demands of automotive tier suppliers.

Key Machining-Specific Standards for Parts

These standards directly define part quality and inspection protocols:

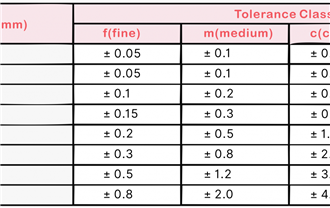

ISO 2768: General Tolerances: This standard provides default tolerance limits for linear and angular dimensions when no specific tolerance is indicated on a drawing, simplifying communication.

ISO 9013: Thermal Cutting: Defines quality levels for thermally cut parts (like laser or plasma cutting), relevant for sheet metal components prior to CNC machining.

Why Certification Matters for Your Project

Choosing a certified supplier offers tangible benefits:

Risk Mitigation: Structured systems catch errors early.

Global Acceptance: Certifications are recognized worldwide.

Assured Traceability: Full documentation for material lots and processes.

Drive for Continuous Improvement: Certified companies are audited regularly, ensuring they evolve and improve.

Conclusion

When sourcing CNC machined parts, the manufacturer's certifications are a direct reflection of their capability and seriousness. For prototypes or non-critical parts, ISO 9001 may suffice. However, for mission-critical applications in aerospace, medical, or automotive fields, the relevant industry-specific certification is non-negotiable. Always verify certifications and discuss how the supplier's quality system applies to your specific project needs.

Ready to partner with a certified precision machining expert? Contact Us to discuss your quality requirements.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 332 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China