Factors Affecting CNC Machining Parts Cost: A Comprehensive Pricing Analysis

Date:2026-01-30Article editor:Starting Point PrecisionViews:30Understanding the cost drivers behind CNC machined parts is crucial for effective budgeting and design optimization. While CNC machining offers unparalleled precision, several interconnected factors determine the final price. This analysis breaks down the primary elements that impact your project's cost.

1. Material Selection: The Foundation of Cost

The choice of material is often the most significant cost driver. Exotic alloys like titanium or Inconel are substantially more expensive than standard aluminum or brass. Material cost encompasses the raw billet price, waste (from the machined-away material), and availability. Standard-grade materials are more cost-effective. For guidance on material properties, consider external resources like the ASM Materials Database.

2. Part Design & Complexity: Engineering Time is Money

Design complexity directly impacts programming time, machining time, and required tolerances.

Geometry: Simple shapes are faster to machine. Complex 3D contours, deep pockets, and thin walls require specialized toolpaths, longer cycle times, and sometimes custom tools.

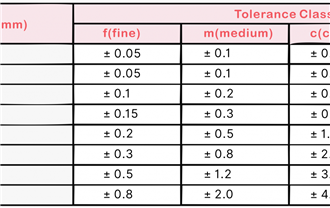

Tolerances: Holding extremely tight tolerances (±0.025mm vs. ±0.125mm) demands slower machining speeds, finer finishing passes, and increased inspection time, raising costs exponentially.

Design for Manufacturability (DFM): A design optimized for machining minimizes cost. Our internal DFM guide offers tips like standardizing hole sizes and avoiding unnecessary tight tolerances.

3. Machining Time & Labor: The Core Expense

The time the machine spends producing your part is a central cost component. Machine time is calculated from cycle time, which depends on:

Part Size and Volume: Larger parts use more material and take longer.

Toolpaths & Operations: Complex parts require more operations (milling, turning, drilling). Efficient CAM programming is key.

Machine Type: Multi-axis (5-axis) machining can complete complex parts in one setup but has a higher hourly rate than 3-axis machines.

4. Production Volume & Setup

CNC machining follows an economy of scale, but differently than molding.

Low Volume/Prototyping: High cost per part due to fixed setup and programming costs distributed over few units.

High Volume: Cost per part decreases significantly as setup costs are amortized. However, pure CNC machining may become less economical than casting or stamping at very high volumes.

5. Post-Processing & Finishing Requirements

Raw machined parts often require additional finishing, each adding cost and time.

Standard Deburring: Usually included.

Surface Finishes: Bead blasting, anodizing, plating, or painting add steps and cost. Specifications from organizations like SAE International may apply.

Special Treatments: Heat treatment or specialized coatings require third-party services.

6. Other Contributing Factors

Quality Control & Inspection: First-article inspection (FAI) and statistical process control (SPC) for critical parts add cost but ensure quality.

Administrative & Logistics: Order administration, expedited shipping, and packaging also factor into the final quote.

Conclusion

CNC machining cost is a function of Material + Design + Time + Quantity + Finishing. The most effective way to manage cost is through early collaboration with your manufacturing partner. Simplifying design, choosing appropriate materials and tolerances, and considering DFM principles can lead to significant savings without compromising part quality. For a detailed quote on your specific project, contact our engineering team today.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 332 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China