Easy-to-Assemble CNC Machining Parts: Simplify Installation Processes

Date:2026-01-30Article editor:Starting Point PrecisionViews:27In product development, the true cost of a component extends beyond its purchase price to include assembly and installation. Complex, fiddly parts can bottleneck production, increase labor costs, and lead to field service failures. This is where the strategic design of easy-to-assemble CNC machining parts delivers immense value, transforming installation from a challenge into a streamlined, error-proof process.

The Core Principle: Design for Assembly (DFA)

Design for Assembly (DFA) is a systematic engineering approach that simplifies product structure for easier and faster putting together. When applied to CNC machining, DFA focuses on creating parts that minimize assembly operations, require common tools, and intuitively guide the installer. The goal is to design parts that are difficult to assemble incorrectly. For foundational principles, refer to resources from The Institute for Engineering Design.

Key Design Strategies for Easy Assembly

Minimize Part Count & Promote Modularity

The simplest part to assemble is the one that doesn't exist. A core DFA tenet is reducing the total number of separate components by integrating multiple features into a single, complex monolithic part via 5-axis CNC machining. This eliminates fasteners and alignment steps. Think of a single machined bracket that replaces an assembly of three welded plates.

Standardize Fasteners and Hardware

Specifying a single screw type, size, and drive (e.g., all M4 cap head sockets) throughout an assembly eliminates tool changes and reduces inventory. CNC machining allows for precise, consistent threaded holes and counterbores that perfectly match these standard fasteners.

Incorporate Intuitive Alignment Features

Parts should self-locate. Designed-in features like:

Foolproofing (Poka-Yoke): Asymmetric dowel pin patterns that only allow correct orientation.

Chamfers and Lead-ins: Generous chamfers on pins and holes guide components into place seamlessly.

Registration Surfaces: Clear, machined datums that define how the part sits.

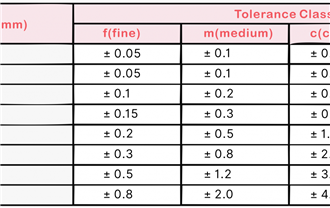

Optimize Tolerances for Fit, Not Just Function

While precision is a CNC strength, needlessly tight tolerances make assembly difficult. Applying Geometric Dimensioning and Tolerancing (GD&T) principles correctly ensures parts fit together as intended without requiring excessive force or adjustment. Our guide on Effective Tolerance Specification offers practical advice.

Clamp & Access Friendly Design

Consider the installer's hands and tools. Ensure there is adequate clearance for a screwdriver or wrench to tighten fasteners. Design open access to clamping points and avoid buried fasteners that are frustrating to reach.

Tangible Benefits for Your Business

Reduced Labor Time & Cost:Reduce costs, increase profits.

Lower Skill Requirement: Error-proof designs allow for reliable assembly by less specialized personnel.

Fewer Errors & Rework: Improve product quality and pass rate.

Enhanced Field Serviceability: Products designed for easy assembly are also easier to disassemble and repair, boosting customer satisfaction.

Implementing DFA: Collaboration is Key

Achieving easy assembly starts at the design stage. Partnering with a CNC machining provider that offers Design for Manufacturability (DFM) analysis is crucial. They can identify assembly pain points in your CAD model and suggest modifications—like adding a lead-in or standardizing a hole size—that have minimal impact on function but maximum impact on assemblability.

Conclusion

Investing in the design of easy-to-assemble CNC machined parts is an investment in operational efficiency, product quality, and total cost reduction. By embracing DFA principles—simplification, standardization, and intuitive guidance—you transform the final installation phase from a variable cost center into a predictable, swift, and reliable process.

Ready to simplify your next project? Submit your design for a free DFM/DFA analysis and see how we can optimize your parts for effortless assembly.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 332 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China