5-Axis Machining Center: The Powerhouse for High-Precision Complex Parts

Date:2026-01-01Article editor:Starting Point PrecisionViews:114In the world of advanced manufacturing, where components grow more intricate and tolerances tighter, the 5-axis machining center stands as a pivotal technology. Moving beyond the limitations of traditional 3-axis machines, it empowers engineers to produce highly complex, high-precision parts in a single setup, revolutionizing speed, accuracy, and design possibilities.

A 5-axis CNC machine manipulates a tool or a part along five different axes simultaneously: the three linear axes (X, Y, Z) and two rotational axes (typically A and B). This dynamic movement allows the cutting tool to approach the workpiece from virtually any direction, enabling the machining of intricate geometries—like those found in aerospace components, medical implants, or automotive prototypes—that would be impossible or inefficient with fewer axes.

Single-Setup Precision: The most significant benefit is completing a complex part in one clamping. This eliminates errors accumulated from multiple setups, ensuring exceptional high-precision and perfect geometric alignment between features. Explore our capabilities for high-precision CNC machining.

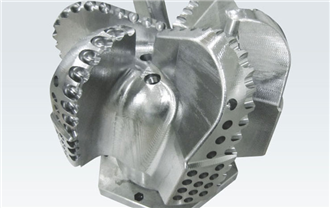

Complex Geometry Mastery: It excels at machining contoured surfaces, undercuts, deep cavities, and angled features without costly special fixtures. This is crucial for parts like turbine blades, impellers, and structural airframe components.

Enhanced Surface Finish: By optimally orienting the tool, it can maintain a consistent cutting posture and use shorter tools at higher speeds, resulting in superior surface quality and reduced need for secondary finishing.

Dramatically Reduced Lead Times: Consolidating multiple operations into one setup slashes non-cut time, handling, and queueing, accelerating the entire production process from prototype to final part.

Aerospace & Defense: For manufacturing lightweight, robust structural components, engine parts, and intricate airfoils from challenging materials like titanium and Inconel. The German Machine Tool Builders' Association (VDW) highlights the critical role of such advanced CNC technology in aerospace. Learn more from this industry resource: VDW on Advanced Manufacturing.

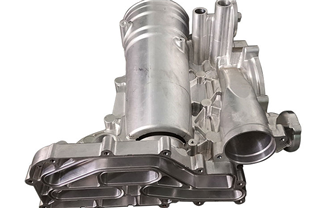

Automotive & Motorsport: Creating high-performance engine blocks, cylinder heads, and lightweight chassis components that push the limits of efficiency and strength.

Energy & Mold-Making: Fabricating complex turbine components and high-precision molds for injection molding with intricate cooling channels.

Selecting a partner for your complex parts project requires evaluating their technical expertise, machine portfolio, and quality systems. Look for:

Advanced Machine Technology: Modern machines with volumetric accuracy compensation and thermal stability.

Engineering Proficiency: Skilled programmers who can leverage 5-axis toolpaths efficiently.

Robust Metrology: In-process probing and access to CMMs for rigorous high-precision verification.

Material Experience: Proven track record with the specific alloys, composites, or plastics your project requires.

The 5-axis machining center is more than just a machine; it's an enabler of innovation. By investing in this technology or partnering with an expert who has, you unlock the ability to design and manufacture the next generation of complex, high-performance parts with unprecedented speed and precision. It transforms manufacturing challenges into competitive advantages, paving the way for breakthroughs across critical industries.

Copyright © 2019 All Rights Reserved Dongguan Starting Point Precision Technology Co., Ltd. Tel: +86-769-82855591

Add: No. 332 Zhen'an Middle Road, Chang'an Town, Dongguan, Guangdong, China